At Corbeto’s we have always felt proud to offer our customers the best boots in the market. Our main goal is bringing the best brands, taking special care to product’s creation, manufacturing and raw material selection.

That’s why, today we are pleased to introduce you Red Wing, one of the brands which we are official dealers. And the thing is that the centenarian Red Wing is not an ordinary brand. Located at the village with the same name, is one of the very few american companies that makes all its production in the United States, following the same construction methods used when was created at beginnings of 20th Century. The result is a line of excellent and high quality handcrafted boots; tough to resist harsh battles, but soft enough to care your feet.

A teenager’s dream

Red Wing Shoe’s Company history has the classic components of an accomplished american dream. At the end of 19th Century, Charles Beckman, a 17 years old german immigrant arrives by train to a Minessota’s little village called Red Wing. His first employment was in a leather tannery and there was where he started to develop his interest about boot’s production.

Shortly after, he opened a shoe store inspired by the aim of only selling high quality boots. But the business didn’t succeed and was forced to shut down. Anyhow, he know that finding good quality boots is something difficult. So he decided turning into producer.

Shortly after, he opened a shoe store inspired by the aim of only selling high quality boots. But the business didn’t succeed and was forced to shut down. Anyhow, he know that finding good quality boots is something difficult. So he decided turning into producer.

This way, on 1905, and thanks to the help of 14 investors that shared his dream, Charles Beckman founded Red Wing Shoe Company. The original factory (known as Plant 1) was located in the corner of Main Street and Potter, and the first boot produced was a work boot, made of leather with buckles and laces for a safer fitting.

Later on, during the 20’s, business lines were expanded in two ways. On one side, at the beginnings of the decade with the creation of work boots for specific jobs. By other, in 1926, with the development of the first ladie’s collection, the called Gloria boot.

Aditionally, in the year 1940 the mobile boot store was also a great innovation: authorized dealers drove across the country with a caravan full of Red Wing boots, to reach the customers at their workplace. This innovative commercial project lasted until 1964.

It was that year when the second production plant was constructed, (known as Plant 2) and where nowadays many of the boots are still made with the same tools and machinery.

In 1986, Red Wing bought S.B. Foot Tanning Company, a leather tannery also located in the village. This way, Red Wing Shoes became one of the very few boot factories that controls the whole production process.

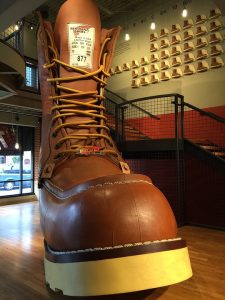

In the year 2005, the company celebrated its Centenary by constructing a giant leather boot of almost 5 meters high and a weight of more than 1000 Kilos. Worth to be at the Guinness records!!!

Boots made old-style

If there is something that distinguish Red Wing boots is the level of craftmanship and accuracy that every pair is produced, making clear that behind each boot there is an artisan that takes care, above all, about the quality.

Before a boot is finished, the raw materials and components wich is made of will follow more than 30 different steps and pass through the hands of 100 people.

To explain it in an easy way, we can summarize the process to create a Red Wing boot as follows:

- Leather cut: the process to produce footwear, without too many changes since Red Wing was founded, starts by cutting the leather pieces necessary for a boot. Skilled cutters place the die cutters over every leather piece. Because there are not two leathers exactly equals, selecting the best pieces is something that only the most skilled artisans can do.

- Leather stitching: the already cut leather pieces are sewed to conform the upper part of the boot, so the stitching machines skilled operators require a careful hand-eye coordination. The same Puritan sewing machines used when Red Wing was founded are still on use nowadays. In fact, many of these machines are operational since 1920.

- Spread out: during the spread out proccess of the front part, the adjusted upper part expands over the boot, to bring the deffinitive shape. The leather panel is welted to the upper insole and the leather sole using the Goodyear welt system pattented in 1869.

- Base: the outsole is welted or glued to the inner sole, to complete production process.

- Finishing: before being packed in boxes, all the boots are carefully inspected for two times. Also, deppending of the leather, each boot is cleaned, brushed and get final treatments by a team of experts.

Red Wing in Corbeto’s Boots

In 1905, Charles Beckman started an excellence standard in the world of the american boots. And now you have the chance to get one of them in our store in Las Ramblas of Barcelona or at our online shop.

Red Wing has two production lines: one is the american line, much more focused in work boots, not available in Europe; and by other side we have the Red Wing Heritage line, based upon the styles that originated the brand. This Heritage collection is the one that can be found in our catalog, a line of footwear inspired by the hard work and made with high quality premium leathers locally produced at its own tannery S.B. Foot Tannery.

Red Wing boots are long lasting and tough but also elegant and have a pleasant touch on the feet. They are made to resist the hard work, so our feet doesn’t have to carry all the workload.